Copper Cable Testing and certification

Copper cable testing and certification are vital elements in ensuring the reliability and performance of communication cabling infrastructure.

With the Viavi 40G Certifier, Anritsu Pim Master, Site Master, Fluke DSX Versiv, or one of our other copper cable testing and certification machines, NDC offers cutting-edge solutions for nearly any copper network certification requirements.

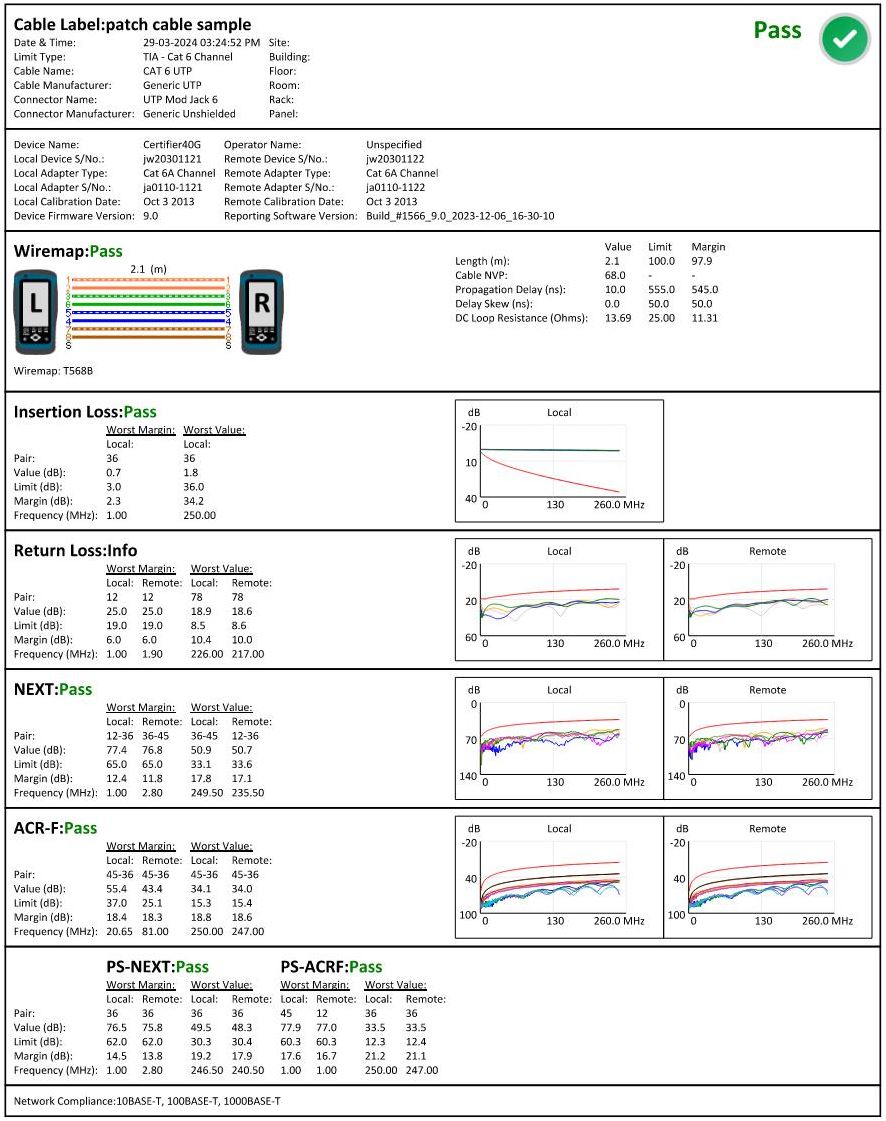

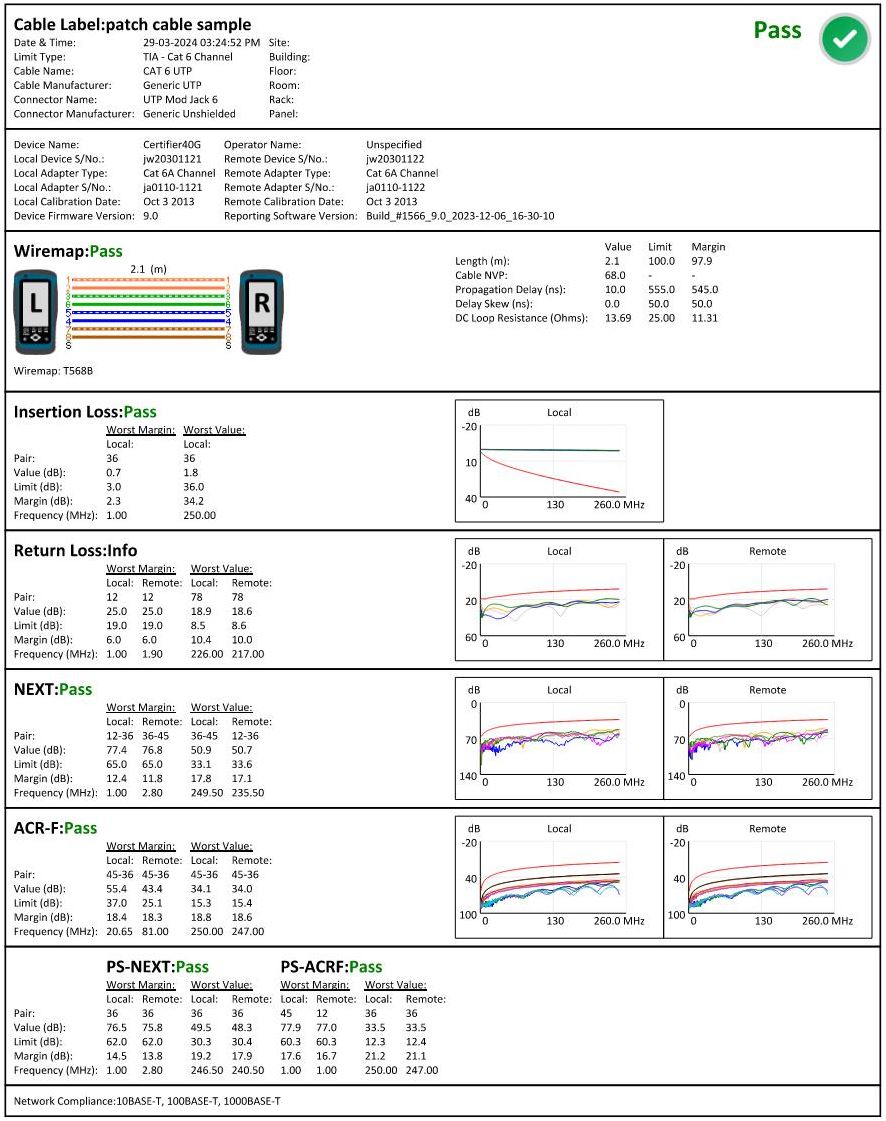

Our certified technicians utilize advanced testing equipment to assess the quality and integrity of copper cabling installations, identifying potential issues and ensuring compliance with industry standards. Our certifiers enable precise measurements of parameters such as signal attenuation, impedance, and crosstalk, providing actionable insights for optimizing network performance, and can even certify to cat 8 network cable!

Our certified technicians utilize advanced testing equipment to assess the quality and integrity of copper cabling installations, identifying potential issues and ensuring compliance with industry standards. Our certifiers enable precise measurements of parameters such as signal attenuation, impedance, and crosstalk, providing actionable insights for optimizing network performance, and can even certify to cat 8 network cable!

By partnering with NDC for your copper cable testing and certification needs, businesses can ensure the efficiency and reliability of their communication networks, reducing the risk of downtime and costly repairs, or sub-par performance. Our expertise and state-of-the-art equipment provides you with comprehensive copper cable testing and certification services, thus empowering your organization with an optimized and dependable communication infrastructure.

In addition to validating copper cabling integrity, the Viavi 40G Certifier, or any of our other machines offers comprehensive certification reports, providing detailed documentation of test results for compliance and auditing purposes. NDC's skilled technicians leverage our certifier's capabilities to diagnose and troubleshoot network issues swiftly, ensuring optimal performance and minimizing downtime. With precise measurements and thorough analysis, we can confidently deploy copper communication systems that meet stringent industry standards and performance requirements. National Data Contractor provides reliable copper cable testing and certification services backed by cutting-edge technology and industry expertise. Ensure the longevity and efficiency of your communication infrastructure with our comprehensive testing solutions and vast range of experience across many machines.

Copper Cable Testing and Certification Overview:

Category Cable - Testing copper Cat cables to meet TIA 568 (Telecommunications Industry Association) and industry standards involves a meticulous process to ensure optimal performance and reliability. Here's an overview of the steps involved:

-

Preparation: Before testing begins, technicians must prepare the testing equipment, including the cable analyzer (such as the Viavi 40G Certifier or Fluke DSX Versiv), test cables, link and/or channel adapters. They also need to ensure the proper calibration of the equipment to maintain accuracy.

-

Visual Inspection: The first step is to visually inspect the Cat cables for any physical damage, such as kinks, bends, or cuts. Any defects found during this inspection must be addressed before proceeding with testing.

-

Wire Mapping: Next, technicians perform wire mapping to ensure that each conductor within the cable is correctly terminated and connected to the appropriate pin on the connectors. This verifies the integrity of the cable's connections and helps identify any wiring errors.

-

Continuity Testing: Continuity testing is conducted to verify the integrity of the connections between the cable's ends. This ensures that there are no breaks or discontinuities in the conductors, which could lead to signal loss or degradation.

-

Length Measurement: Precise length measurements are essential to ensure that the Cat cables meet industry standards for maximum run length limits. The cable analyzer is used to accurately measure the length of each cable segment, accounting for any twists, bends, or turns in the cable path.

-

Resistance and Impedance Testing: Resistance and impedance testing assess the properties of the copper conductors within the Cat cables. This helps identify any irregularities or anomalies that could affect signal transmission and performance.

-

NEXT, FEXT & AXT Testing: Near-end crosstalk (NEXT), far-end crosstalk (FEXT), and Alien cross talk (AXT) evaluate the potential for interference between adjacent cable pairs and from external sources, respectively. These tests assess the cable's ability to maintain signal integrity in the presence of crosstalk, which is critical for reliable data transmission.

-

Insertion Loss Testing: Insertion loss testing measures the attenuation of the signal as it travels through the Cat cables. This helps determine the cable's ability to maintain signal strength over distance and ensures compliance with industry standards for signal loss limits.

- We test to TIA 568-C.2 Cat 5e, 6, 6A ISO/IEC 11801, EN 50173 Class D, E, EA, and can even certify up to TIA 568-C.2-1 Cat 8 ISO/IEC 11801, EN 50173 Class F, FA.

-

Certification: Once testing is complete, technicians generate a comprehensive test report using the cable analyzer software. This report documents the test results and confirms whether the Cat cables meet TIA and industry standards for performance and quality.

-

Documentation: Finally, technicians provide clients with detailed documentation of the testing process and results, including the test report, length measurements, and any recommendations for remediation or improvement. This documentation serves as proof of compliance with standards and ensures transparency and accountability in the testing process.

PIM Analysis - Static and Dynamic Testing:

A Passive Intermodulation (PIM) sweep test is a crucial procedure for assessing the quality and performance of cellular communication systems, especially in distributed antenna systems (DAS). Our techs conduct PIM sweep tests effectively:

-

Equipment Setup: We begin by ensuring that all necessary equipment, including a portable PIM analyzer, test cables, adapters, and connectors, are properly set up and calibrated according to manufacturer specifications.

-

Frequency Range Selection: We determine the frequency range over which the PIM sweep test will be conducted, typically spanning the operational frequencies of the cellular network.

-

Test Configuration: The PIM analyzer is connected to the DAS system or antenna under test using appropriate cables and adapters, and configured to sweep across the selected frequency range while measuring PIM levels.

-

Test Execution: The test is initiated and a scan performs the sweep through the frequency range, monitoring and recording PIM levels at each frequency point. We usually run a static test first to eliminate any movement in the components and give a true measurement, as movement of components can skew the results and mask the standing issue. We then do a dynamic test once all static PIM issues are cleared. A dynamic test involves transmitting multiple simultaneous signals through the system while varying the power levels and frequencies, and also manipulating the components, sometimes called a shake, tap, and bend test, to test bad connections or cable. This test simulates real-world operating conditions and identifies potential sources of PIM under dynamic load scenarios.

-

Analysis and Interpretation: Once the test is complete, we analyze the collected data to identify any spikes or peaks in PIM levels, which indicates the presence of intermodulation distortion caused by nonlinearities or imperfections in the system components.

-

Troubleshooting and Remediation: Based on the test results, we troubleshoot and identify potential sources of PIM, such as loose connectors, corroded cables, or damaged components, then take corrective actions to mitigate PIM issues and optimize the performance of the cellular communication system.

-

Documentation: We document the PIM sweep test results, including PIM levels at various frequencies, any identified sources of PIM, and the actions taken to address them. Our final performance documentation serves as a valuable reference for future maintenance and optimization efforts.

Cable Loss Sweep Measurement:

We configure the sweep and by setting the start and stop frequencies. This will depend on the frequency range needed to sweep test. We dial in the desired number of data points for the sweep and look at the results:

- Cable Loss or Attenuation: Measures how much the signal strength decreases as it travels through the cable. This loss, often expressed in decibels (dB), is due to factors such as resistance, dielectric losses, and radiation losses within the cable.

- Frequency Response: By sweeping across a range of frequencies, the test can reveal how the cable's loss characteristics vary with frequency. This is important because different applications may require transmission of signals at specific frequencies, and the cable should ideally perform consistently across those frequencies.

- Impedance Matching: Detects impedance mismatches along the cable. Impedance mismatches can lead to signal reflections, resulting in additional loss and potentially degrading signal quality.

- Cable Integrity: Identifies any physical damage or defects in the cable that may contribute to increased loss or impedance mismatches. This includes issues such as connector damage, insulation degradation, or conductor breakage.

- Performance Verification: The above results for cable loss sweeps are used for quality of signal, ensuring that the cables meet specified performance standards and requirements for a given application.